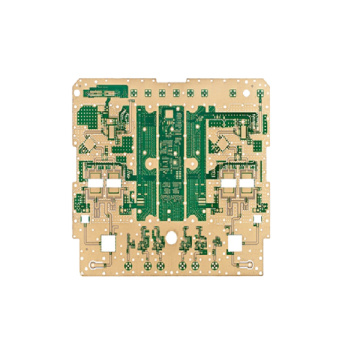

Quick Turn PCB High frequency board PCB

Basic Info

Model No.: Quick Turn PCB High frequency board PCB

Product Description

What is high frequency PCB?

The high frequency board refers to the special circuit board with higher electromagnetic frequency. PCB used in high frequency (frequency greater than 300MHZ or wavelength less than 1 meter) and microwave (frequency greater than 3GHZ or wavelength less than 0.1 meter) is a part of the process or use of common rigid circuit board manufacturing methods on microwave base copper clad laminates Circuit boards produced by special processing methods. Generally speaking, in PCB proofing, the high-frequency board can be defined as a circuit board with a frequency above 1GHz!

In PCB proofing, the classification and processing methods of high-frequency boards:

Type A: NPTH PTFE sheet

1. Manufacturer:

Rogers’ 4350B/4003C, Arlon’s 25N/25FR, Taconic’s TLG series

2. Processing method:

The processing method is similar to epoxy resin/glass woven cloth (FR4) in PCB proofing.

3. Processing flow:

Cutting-Drilling-Dry Film-Inspection-Etching-Erosion Inspection-Solder Mask-Characters-Spray Tin-Forming-Testing-Final Inspection-Packaging-Shipment

Type B: PTH PTFE sheet

1. Manufacturer:

Rogers' RO3000 series, RT series, TMM series, Arlon's AD/AR series, IsoClad series, CuClad series, Taconic's RF series, TLX series, TLY series, Taixing Microwave's F4B, F4BM, F4BK, TP-2 Wait

2. Processing method:

1. Cutting: The protective film must be kept to prevent scratches and creasing.

2. Drilling

(1) Use a brand new drill bit (standard 130), one by one is the best, the pressure of the presser foot is 40psi;

(2) The aluminum sheet is the cover plate, and then the PTFE plate is tightened with a 1mm melamine backing plate;

(3) After drilling, use an air gun to blow out the dust in the hole;

(4) With the most stable drilling rig, the drilling parameters are basically the smaller the hole, the faster the drilling speed.

3. Hole treatment: plasma treatment or sodium naphthalene activation treatment to facilitate hole metallization.

4. PTH sinking copper

(1) After micro-etching (20 micro-inch control of the micro-etching rate), pull the plate into the plate from the de-oiling cylinder in the PTH pull;

(2) If necessary, pass the second PTH.

5. Solder mask

(1) Pre-treatment: Use acidic plate washing instead of mechanical grinding plate;

(2) Baking plate (90℃, 30min) after pretreatment, brush with green oil to solidify;

(3) Three-stage baking: one section is 80℃, 100℃, 150℃, and the time is 30min each (if you find that the substrate surface is oily, you can rework, wash off the green oil, and reactivate it).

6, gong board

(1) Lay the white paper on the circuit surface of the PTFE board, and clamp it up and down with the FR-4 substrate board or phenolic bottom board with a thickness of 1.0MM etched to remove the copper;

(2) The burrs on the back of the gong board need to be carefully trimmed by hand to prevent damage to the base material and copper surface, and then separated by a considerable size of sulfur-free paper, and visually inspected. To reduce burrs, the focus is on the effect of removing the burr during the gong board process. Be good.

3. Processing flow:

Cutting-drilling-hole treatment (plasma treatment or sodium naphthalene activation treatment)-copper immersion-board electricity-dry film-inspection-diagram electricity-etching-corrosion inspection-solder mask-character-spray tin-molding-test-final Inspection-Packaging-Shipping

Summary: Difficulties in high-frequency PCB proofing

1.Sink copper: the hole wall is not easy to be copper

2. Control of line gaps and sand holes of map transfer, etching, line width

3. Green oil process: green oil adhesion and green oil foaming control

4. Strictly control board surface scratches in each process.

Product Categories : High Frequency Board > HDI PCB