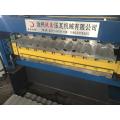

Double layer roll purlin forming machine

Basic Info

Model No.: Customized

Product Description

Double layer roll purlin forming machine

Product Description

We are the specialized manufacturer in producing Double Layer Roofing Sheet Roll Forming Machine all kinds of roll forming machines, such as glazed tile roll forming machine, roof/wall panel roll forming machine, double layer roll forming machine, C & Z purlin machine, floor deck roll forming machine, highway guardrail machine, dust shield machine, ridge cap machine, roll shutter door machine, uncoiling & leveling & slitting & recoiling line, all kinds of decoilers and stackers, and many other related equipments like shear, punch, slitter, leveler, crimping curving, bending and so on. double layer glazed tile roll forming machine

Machine parameters

| Item | Parameter | |

| Suitable Material | Type | PPGI/GI/PPGL |

| Thickness | 0.3-0.8mm | |

| Wide | 914mm/1000mm/1200mm/1250mm/1450mm | |

| Yield Strength | 230~550MPA | |

| Product Specs | Profile | Customized profile |

| Effective width | Base on customized profile | |

| Length | Any length | |

| Power Specs | Voltage | 380V/3PH/50HZ, accept customization |

| Main Motor | 5.5kw | |

| Hydraulic motor | 4kw | |

| Hydraulic pressure | 10-12MPa | |

| Machine Specs | Forming steps number | 13~20 steps |

| Shaft Material | 45 # steel tempered,Φ70~90mm | |

| Roller Material | 45 # steel chrome coated | |

| Main machine body | 350# H steel welded | |

| Transmission | Chain and Sprocket, chain size 1.5 inch | |

| Wall Plate | 16mm thickness | |

| Blade material | Cr12 mould steel with quenched treatment 60-62° | |

| Forming Speed | 8-12m/min for standard solution | |

Packaging & Shipping

The machine is naked in the container ,

the computer and pump station are packaged with waterproof .

1. TECHNOLOGY

Customized Design

We can special design production lines to meet different customized requirements.Our teams specialize in mechanical design,electric design, process design, formula design, workshop and plant design, and etc

Our company innovate continously, constantly absorbing domestic and overseas advanced technology, communicating and cooperating with the experts in relative fields.

2.Quality Control

We have 6 independent QC departments both in the company and factories which strictly control the quality of each process to enable our production lines to reach Chinese National Standards nd International Standards.

CE Certificate

Main production lines have earned CE Certificates and ISO certificate.

3. TEST PRODUCTION

The customer can send their engineers to China to get testing in our downstream factories.

We also can send experienced engineers to instruct the customers to take the test production in customers` workshop, if necessary.

Our company

Cangzhou Dixin Roll Forming Machine Co., Ltd. is specialized in building materials of light steel structure. Since the factory founded 10 years before, it always designs and produces various type profile of roll forming machine.

The main products of factory is Roller shutter door, PU sandwish panel line, pre-painted steel forming machine, Racking roll forming machine, the cable tray roll forming machine,Glazed Tile forming machine, Automatical C/Z Purlin forming machine, Floor Deck forming machine, Guardrail forming machine, Down Pipe forming machine, the whole carriage plate for car beam unit,Steel storage unit, etc. The products are widely used in warehouse, factory buildings, supermarket, Nursing homes, villas and other construction projects, Our factory can meet the construction enterprises, automobile industry, Iron andsteel production enterprises' growing demands.

FAQ

Q:How is this machine's service life?

A:In the normal maintenance,the service life at least 8 years.

Q:How to maintenance?

A:If using frequently,best coating lubricant on the chain and two ends of the shaft every month,replace the hydraulic oil every 1-2 years.

Q:What can you do if the machine broken?

A:Our machine's warranty period is 1 year,if the broken parts can't repair,we can free send the new parts replace the broken parts to you except the Solenoid valve,the Solenoid Valve you must pay the express cost yourself.if after warranty period,we can through negotiationfor to solve the problems,and we supply the technical support for the whole life of the equipment.

Q:Can you be responsible for transport?

A:Yes,please tell me the destination port or address.we have rich experience in transport.

Q:Mr.Alan,can you make the machine according to my design or proto type?

A: Yes. We have an experienced team for working out the most suitable design and production plan for the machine that you are going to book with us.

Q:How many workers operate this machine to manufacture?

A:Only 1-2 worker.

Q:Can you supply the raw materials?

A:Yes,we can supply the galvanized steel coil,steel coil,color steel coil,and aluminum coil.

Customers

![JRK%{9QS]~]SOIS4PNUKSMA JRK%{9QS]~]SOIS4PNUKSMA](http://i.glbin.com/product/8b/4f/15/75b7b9e021540014379559e7dd.png@watermark=2&color=I0ZGRkZGRg%3D%3D&type=ZHJvaWRzYW5zZmFsbGJhY2s%3D&size=21&p=5&t=80&text=Y3pkeG1hY2hpbmUuYm9zc2dvby5jb20%3D)

Welcome to our company!

If you have any question, please feel free contact me !

![FR]W4W`1~`BX8)M(9)RH7(7 FR]W4W`1~`BX8)M(9)RH7(7](http://i.glbin.com/product/1f/a3/7b/7f20c64a1d1aa7004448dc6839.jpg@watermark=2&color=I0ZGRkZGRg%3D%3D&type=ZHJvaWRzYW5zZmFsbGJhY2s%3D&size=21&p=5&t=80&text=Y3pkeG1hY2hpbmUuYm9zc2dvby5jb20%3D)

Product Categories : Double Deck Roll Forming Machine